Over time, I became convinced that there was a gasket leak of combustion gas into the coolant system. No other symptoms such as oil in the coolant or mayonnaise in the oil were apparent.

The van has overheated four times under my ownership, that I know of:

- months ago, on the drive from cold after a vacuum fill

- a couple of weeks later, badly, in slow traffic, up to 105 degC, kept driving to clear the motorway, front heater blowing hot, cold, hot, cold, etc..., bled in a car park then drover >1300 miles, going pffft every 15 minutes or so.

- a month or two ago, coming back from the Red Squirrel, up to 98 degC, caught very quickly

- a couple of weeks ago, during normal driving, up to 96 degC but resolved itself.

I first installed a coolant pressure sensor at the end of the bleed hose using a couple of airline couplings and some epoxy putty. This got me some readings, including "vent events" where the header tank cap would blow off pressure. I experienced a little coolant loss from here, but no noticeable drop in level was apparent.

I then confidently drilled a hole in the header tank and installed another sensor there, again with putty. I drilled another hole to fit the working sensor (the one I'd installed first was one I had blown by fitting the connector the wrong way round). This then became the source of a pressure leak itself and despite several more applications of epoxy putty and two-part epoxy, continued to leak.

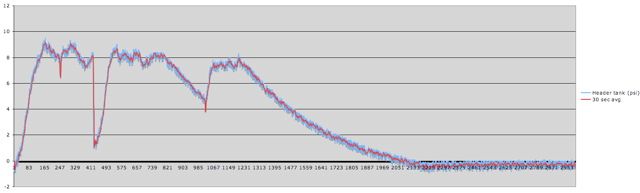

While I had this pressure leak and was monitoring pressure at the header tank, I got some traces that correlated pressure rise with the use of my right foot. Driving gently, I'd managed a couple of thousand miles and become increasingly convinced that the gasket had gone.

On removing the old thermostat, I discovered that I had incorrectly replaced it last time I had it out to pan test. The rubber gasket was still held against the flat surface of the upper thermostat housing and I had simply put the thermostat into the recess of the bottom and bolted it together - like a duvet rather than a sleeping bag, if you know what I mean. Ady and I both noticed a small drip from there so it is conceivable that I had been sucking air into that point as the system cooled. As I said, there was no noticeable drop in coolant level in the header tank over time, so I don't think it was leaking badly at all.

I removed the head, decked the block, replaced the gasket and applied Stag Wellseal to block and head upon refitting, having the head neither cold or hot pressure tested, nor skimmed.

Still with a leaky header tank, I have conducted half a dozen road tests and in each case, the pressure is no longer rising as it did under load. I can assume therefore that a) the head itself is ok, and b) the gasket replacement was successful.

I've peaked at around 10.5 psi during the last few road tests, having incrementally lessened the pressure leak from my old header tank but it still drops off over time. Drives ok, but not ideal to habitually run a van with a weakly pressurised coolant system, despite the system being unpressurised after bleeding and getting the 'stat open immediately before a drive. A van should be left to cool somewhat after bleeding and before driving.

Peterrc brought his spare header tank round last week (for which I need to pay him, still...).

I used a little fabric oxy powder to soak it then rinsed it out. Biting the bullet again, and with the benefit of hindsight/experience, I fitted a pressure sensor to it, too, on the small hollow blanked stub on the top left. Putty round the port, pressed in and then coated in two-part epoxy and cured with the aid of a hairdryer.

The logical next step then was a cold pressure test, which I have now completed.

Result: 12psi for 15 minutes - success.

Having seen Ady's pressure switches and dial gauge and discussed the same with others, the idea that while monitoring temperature and coolant level are useful, head-saving techniques, going from first principles suggests that monitoring pressure in a sealed system will give indication of any problem, anomaly or typical behaviour earlier than either level or temperature responds. With the sensors hooked up to the Arduino, LCD and buzzer, I can alarm on an absolute value, rapid rise or rapid fall of pressure.

I have considered several times buying a low coolant alarm, and was prepared to bite the bullet last month if only I could get one with both low- and high- alarms. I couldn't, so I didn't. I've ordered the £10 jobbie from eBay instead.

I've taken so long in doing all this because the van was still running "okay" and I wanted to gather data (graphs) before and after any changes in the system. A normal person would have started with changing the 'stat and bleeding it, rather than going all out and removing the head. In that sense, "I'll never know what fixed it". That bothers me up to a point, but the end goal was regaining the reliability from the van that we need with a winter little'un on the way. And for me to be able to get away from it all the odd weekend.

Is that clearer?