Page 17 of 19

Re: DIY non invasive temperature gauge probe placement ideas

Posted: Tue Sep 13, 2011 8:22 pm

by Rhinoman

I converted the hex file to a binary image and ran it through IDAPro as a 16F874A which is close enough as the PICs are pretty interchangeable. If you can determine the pin designations then the code sections can be defined. The code is rather horrible though, only having 35 instructions means that it takes a load of code to perform a simple function. The easiest way to tackle this could be to write new firmware in C, are you using MPLAB IDE?

Its quite common to drive multiple 7 segment LEDs from a shared bus, if you toggle them fast enough the persistance makes it look they are driven seperately although they are a bit dimmer.

Re: DIY non invasive temperature gauge probe placement ideas

Posted: Wed Sep 14, 2011 12:48 am

by Driver+Passengers

Rhinoman wrote:The code is rather horrible though, only having 35 instructions means that it takes a load of code to perform a simple function.

To me, that makes it more readable!

Rhinoman wrote:The easiest way to tackle this could be to write new firmware in C, are you using MPLAB IDE?

I agree. Downloaded MPLAB IDE a few nights ago - didn't realise it now comes

with C compiler - score!

Other than the alarm function, I'd like to code it such that it performs a 1-wire bus scan (potentially multiple DS18B20s per channel) and if no devices are found, falls back to ADC for NTCs. That said, make it too complicated and there's a significant challenge to design a UI that's usable!

It's all just a bit of fun, though distracting me somewhat from the Arduino project.

tallbongo - might pin 11 already serve two functions?? I can't quite fathom your post-it yet.

Re: DIY non invasive temperature gauge probe placement ideas

Posted: Wed Sep 14, 2011 3:53 am

by Northern Bongolow

Re: DIY non invasive temperature gauge probe placement ideas

Posted: Wed Sep 14, 2011 9:04 am

by bikerbob

As posted the new Sure unit sensors are not calibrated for a common temp readout on both channels and it looks like its hit & miss as to quality & accuracy can you guys look into a method of calibration to ensure both channels can be adjusted to read same

I now only use channel 1 which gives a constant readout as I did find the switching between both channels distracting but would like the option of both.

Re: DIY non invasive temperature gauge probe placement ideas

Posted: Wed Sep 14, 2011 9:49 am

by jaylee

Both sensors on mine (Top hose outlet & heater outlet metal stub.) Before starting the engine, read the same ambient temperature always.. (Maybe both readings a degree or two higher than the air temp due to being to the engine & covered by the van?)

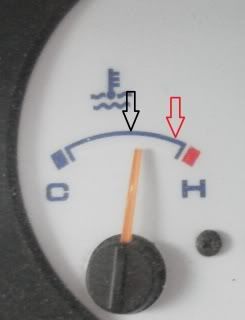

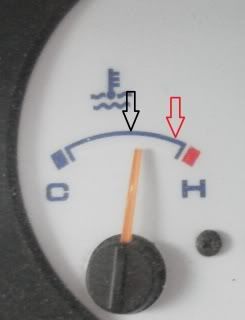

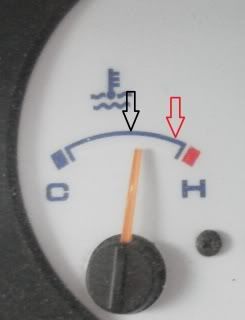

My observations of this gauge also reveal at around 85c on the gauge my Mason gauge can be quite high on odd occasions (Only really going up hills) Up hill at speed however it sits a little cooler, then come down to roughly where you see the needle sat here as the gauge comes up to 91 or 92c on the top hose outlet, the heater stub about 6c lower than the leading temp..(Never any higher.)

If i stop then i let the engine idle to remove heat soak, that's when the heater hose temp joins the top hose temp (Even excelling by a degree the top hose, then they drop a little maybe to around 86/87c? Then as/if i pull away they settle back more...

So am i right in thinking the coolant is doing its job with the engine, removing the excess heat generated?

Though my fans cut in appropriately, the scav fan doesn't... (Scavs been tested & i have fitted a warning lamp to tell if it does cut in.)

Keep up the good work with the mods guys.. I've been following this with great interest!

Re: DIY non invasive temperature gauge probe placement ideas

Posted: Wed Sep 14, 2011 9:54 am

by jaylee

The second unit still hasn't arrived yet for the dual pan test..

Re: DIY non invasive temperature gauge probe placement ideas

Posted: Wed Sep 14, 2011 10:07 am

by bikerbob

The original sure unit & sensors did give the same ambient temperature on both channels however the new unit received & using the original sensors showed a big discrepacy between them, I then connected the new sensors & same result, so this leads me to a conclusion that the new unit/sensors have not been checked for calibration, will be taking this issue up with Sure but as received new unit FOC do not think they will be too helpful.

Re: DIY non invasive temperature gauge probe placement ideas

Posted: Wed Sep 14, 2011 10:14 am

by jaylee

bikerbob wrote:Received the new Sure unit today,

wired in using existing in situ kit from previous unit, at ambient temperature engine cold,

sensor 1 on spigot & sensor 2 on rubber hose there was a 15C reading difference between channel 1&2, decided to try new `3METRE length`sensors plugged into unit but with sensors draped over the steering wheel, ambient reading difference similar which suggests that the unit/sensors have not been calibrated to read same. Road tested the system and everything seems to be working ok apart from the calibration issue, can live with this as I only want to know if & when an overheat situation commences, max temperature recorded on 20 mile road test and at idleing speeds 91C(at spigot) anything above this would investigate header tank level for coolant loss. Due to the difference between channels

1&2 considering only utilising one channel reading off the spigot.

shoot me down in flames you technocarts if you think my reasoning is more muddled than usual.

Look forward to the responses

Have a look at this Bob...

http://www.igmaynard.co.uk/bongo/forum/ ... =3&t=51063

Re: DIY non invasive temperature gauge probe placement ideas

Posted: Wed Sep 14, 2011 11:50 am

by widdowson2008

jaylee wrote:bikerbob wrote:Received the new Sure unit today,

wired in using existing in situ kit from previous unit, at ambient temperature engine cold,

sensor 1 on spigot & sensor 2 on rubber hose there was a 15C reading difference between channel 1&2, decided to try new `3METRE length`sensors plugged into unit but with sensors draped over the steering wheel, ambient reading difference similar which suggests that the unit/sensors have not been calibrated to read same. Road tested the system and everything seems to be working ok apart from the calibration issue, can live with this as I only want to know if & when an overheat situation commences, max temperature recorded on 20 mile road test and at idleing speeds 91C(at spigot) anything above this would investigate header tank level for coolant loss. Due to the difference between channels

1&2 considering only utilising one channel reading off the spigot.

shoot me down in flames you technocarts if you think my reasoning is more muddled than usual.

Look forward to the responses

Have a look at this Bob...

http://www.igmaynard.co.uk/bongo/forum/ ... =3&t=51063

You need to be carefull using that graph as an example Jamie. Whilst valid, it only indicates what happens during the warm-up period (as explained further down in the thread).

I'm currently working on this spreadsheet which is dynamic. By changing each of the variables (of which there are more than shown - work in progress

) the diagram alters, showing the effect at each point indicated. Before anyone gets the guns out, I stress that this is WORK IN PROGRESS, and as such is incomplete.

One thing that may seem odd is that the pump outlet is not the same as the block inlet (which they should be - and in fact ARE)

Reason for this is that being dynamic, the diagram has to have a start point and I've taken this as block inlet (80) and the generated figures around the system are based on this figure. ie: the pump outlet (81.

shown is what happens as a result of that particular block inlet (80)with the variables set as shown. Sorry

- I'm trying to make it simple - Honest guv.

Re: DIY non invasive temperature gauge probe placement ideas

Posted: Wed Sep 14, 2011 12:20 pm

by jaylee

widdowson2008 wrote:jaylee wrote:bikerbob wrote:Received the new Sure unit today,

wired in using existing in situ kit from previous unit, at ambient temperature engine cold,

sensor 1 on spigot & sensor 2 on rubber hose there was a 15C reading difference between channel 1&2, decided to try new `3METRE length`sensors plugged into unit but with sensors draped over the steering wheel, ambient reading difference similar which suggests that the unit/sensors have not been calibrated to read same. Road tested the system and everything seems to be working ok apart from the calibration issue, can live with this as I only want to know if & when an overheat situation commences, max temperature recorded on 20 mile road test and at idleing speeds 91C(at spigot) anything above this would investigate header tank level for coolant loss. Due to the difference between channels

1&2 considering only utilising one channel reading off the spigot.

shoot me down in flames you technocarts if you think my reasoning is more muddled than usual.

Look forward to the responses

Have a look at this Bob...

http://www.igmaynard.co.uk/bongo/forum/ ... =3&t=51063

You need to be carefull using that graph as an example Jamie. Whilst valid, it only indicates what happens during the warm-up period (as explained further down in the thread).

I'm currently working on this spreadsheet which is dynamic. By changing each of the variables (of which there are more than shown - work in progress

) the diagram alters, showing the effect at each point indicated. Before anyone gets the guns out, I stress that this is WORK IN PROGRESS, and as such is incomplete.

One thing that may seem odd is that the pump outlet is not the same as the block inlet (which they should be - and in fact ARE)

Reason for this is that being dynamic, the diagram has to have a start point and I've taken this as block inlet (80) and the generated figures around the system are based on this figure. ie: the pump outlet (81.

shown is what happens as a result of that particular block inlet (80)with the variables set as shown. Sorry

- I'm trying to make it simple - Honest guv.

Steve, your diagram kind of ties in with my observations of the reading of the Mason gauge & the top hose reading on the sure gauge...

At least what i was trying to explain on the earlier post??!!

jaylee wrote:Both sensors on mine (Top hose outlet & heater outlet metal stub.) Before starting the engine, read the same ambient temperature always.. (Maybe both readings a degree or two higher than the air temp due to being to the engine & covered by the van?)

My observations of this gauge also reveal at around 85c on the gauge my Mason gauge can be quite high on odd occasions (Only really going up hills) Up hill at speed however it sits a little cooler, then come down to roughly where you see the needle sat here as the gauge comes up to 91 or 92c on the top hose outlet, the heater stub about 6c lower than the leading temp..(Never any higher.)

If i stop then i let the engine idle to remove heat soak, that's when the heater hose temp joins the top hose temp (Even excelling by a degree the top hose, then they drop a little maybe to around 86/87c? Then as/if i pull away they settle back more...

So am i right in thinking the coolant is doing its job with the engine, removing the excess heat generated?

Though my fans cut in appropriately, the scav fan doesn't... (Scavs been tested & i have fitted a warning lamp to tell if it does cut in.)

Keep up the good work with the mods guys.. I've been following this with great interest!

If i am looking at the work in progress right?

Re: DIY non invasive temperature gauge probe placement ideas

Posted: Wed Sep 14, 2011 2:43 pm

by widdowson2008

Hi Jamie - Yep, you're seeing it OK by my reckoning (we may both be a mile out of line of course

)

Re: DIY non invasive temperature gauge probe placement ideas

Posted: Wed Sep 14, 2011 3:43 pm

by jaylee

widdowson2008 wrote:Hi Jamie - Yep, you're seeing it OK by my reckoning (we may both be a mile out of line of course

)

Hey Steve, i don't mind if anybody wants to put me right....

I've found quite often before i've been "mistaken about a great many things"..

Blah blah dark side... Now witness the fire power of this fully armed & operational battle station...

(Sorry wrong thread.)

Re: DIY non invasive temperature gauge probe placement ideas

Posted: Wed Sep 14, 2011 6:54 pm

by Driver+Passengers

tallbongo wrote:I've not measured all the 7 segments... However they do seem to be reasonably consistent, but not all. The non-consistencies are probably enables and possibly the top segment you are having problems with.

The small 7-segment which only displays the sign seems to only be connected on one segment. It make sense that this is the middle segment and it is connected to pin 5. Hopefully this is consistent with your findings.

So the three main digits are normal, and the final C/F is wired upside down. That's why in my simulator the last digit was always '3' with a missing the top segment!

I haven't identified exactly which is the signal for the negative sign, but should be easy enough. I've traced through a great deal of the code, and have even made a couple of modifications to it running in the simulator. And found and fixed a bug (I think I introduced it). I can't quite bridge the gap from where the sensors are read to where the LEDs are output. I think there's a combination of indirect addressing and pointer arithmetic. Anyway, progress of sorts.

Bob - I look forward to receiving the unit. As promised, if I pimp it successfully, you are welcome to have it back! I will try not to trash it...

PS. I'm half wondering if we should split out to a 'Deconstructing the Sure Temperature Sensor' thread as it is likely to go on a bit - we've only just got started!!!

. Anyone else agree?

Re: DIY non invasive temperature gauge probe placement ideas

Posted: Wed Sep 14, 2011 7:06 pm

by jaylee

Yep i agree DP!!

Initially i only wanted to know where to stick a probe.... But i'm finding your input fascinating

.

A 'Deconstructing the Sure Temperature Sensor' thread would be a great idea!