Quick electrical question

Moderators: Doone, westonwarrior

Quick electrical question

Drivers door Leckie windo switch is intermittent. Can get it to work by wiggling the loom between the door so must be a break somewhere. Speaker can be intermittent aswell. Comes off and on when you open and close the door. I know I need to fix a new piece of wire in but is there a specific type of wire to use? Or is there some more hard wearing than others? Was going to get some bullet or block connectors so I can just swap it out should it go again in the future. Any one got any better ideas?

- Northern Bongolow

- Supreme Being

- Posts: 7723

- Joined: Mon Mar 15, 2010 11:33 pm

- Location: AKA Vanessa

Re: Quick electrical question

the bongo shop sells a new loom, plug and play

Re: Quick electrical question

Yeah but it's 86 quid and out of stock. I don't know much about electrics hence the wire question. Is there standard auto electric wire?

Re: Quick electrical question

Find the break, slip a bit of heat shrink tubing over one end of the wire, solder it up and shrink the tubing over it.

I'd try to avoid connection blocks etc as they can fail over time and take up room.

I'd try to avoid connection blocks etc as they can fail over time and take up room.

Re: Quick electrical question

Agreed!briwy wrote:Find the break, slip a bit of heat shrink tubing over one end of the wire, solder it up and shrink the tubing over it.

I'd try to avoid connection blocks etc as they can fail over time and take up room.

It's a fiddly job, but the loom can be repaired satisfactory & in situ...

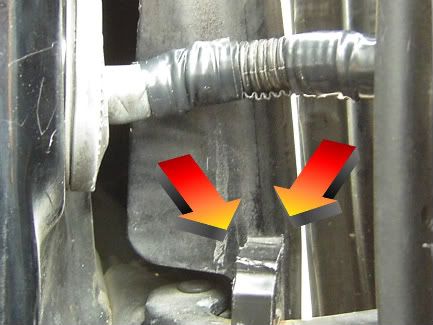

There are basically two places the wires can break. either as it goes through the grommet to the body (somtime under the sheath on the grommet out of sight when the loom cover is removed.) or on the bottom V where the loom ties to the hinge...

Solder & shrink=wrap is the best course of action to do a solid long term repair..

I also set about taking up any slack in the loom in the driver footwell, dispensing with the V in the loom altogether.. (I reckon the V causes more problems with the loom in the long run than it solves.?)

Done like this, it moves with the door causing less stress on the loom & repair work done...

You may find the loom cover/conduit will be split at the V? Just cut it in half & use the best bit to re-house the loom..

I call it the "T4" door loom set up after getting the idea from a works van a few years back....

I've done about 3 other Bongo's like this with varying degrees of loom carnage over the years, & haven't had any comeback as yet regarding the longevity of repair...

I'd say save yer 86 find someone who can solder & hold the door steady for em...

Cheaper by comparison to a race horse...

Re: Quick electrical question

If you take off the plastic cheek trim in the footwell you can undo the two plugs and it is then an easy matter to remove the door card and pull the damaged bit and the plugs out through the doorframe. This gives you much better access to do the repair. I got that far but found nearly all the wires were broken or brittle and went fot the new loom instead. I missed out the clip as recommended by Jaylee but to stop it touching the back of the doorskin I anchored it to the empty clip with a loop of about three layers of self amalgamating tape with some frapping turns to make it like a figure of eight,jaylee wrote:Agreed!briwy wrote:Find the break, slip a bit of heat shrink tubing over one end of the wire, solder it up and shrink the tubing over it.

I'd try to avoid connection blocks etc as they can fail over time and take up room.

It's a fiddly job, but the loom can be repaired satisfactory & in situ...

There are basically two places the wires can break. either as it goes through the grommet to the body (somtime under the sheath on the grommet out of sight when the loom cover is removed.) or on the bottom V where the loom ties to the hinge...

Solder & shrink=wrap is the best course of action to do a solid long term repair..

I also set about taking up any slack in the loom in the driver footwell, dispensing with the V in the loom altogether.. (I reckon the V causes more problems with the loom in the long run than it solves.?)

Done like this, it moves with the door causing less stress on the loom & repair work done...

You may find the loom cover/conduit will be split at the V? Just cut it in half & use the best bit to re-house the loom..

I call it the "T4" door loom set up after getting the idea from a works van a few years back....

I've done about 3 other Bongo's like this with varying degrees of loom carnage over the years, & haven't had any comeback as yet regarding the longevity of repair...

I'd say save yer 86 find someone who can solder & hold the door steady for em...

[url]http://germanshepherdrescue.co.uk/[/url]

Re: Quick electrical question

Gonna take it apart next week so will see what route I go down. If its totally goosed I might just change it if I can get one cheap enough!!