I posted in April about the control principles for the Bongo cooling system, and there was a query what did I mean by re-circ flow. Been off the forum for some time so have not been able to reply. However, have got back to find a good animation which helps in understand the dynamic nature of the cooling circuits.

Last year in France I replaced a burst hose and got a good description of the bleed process off the forum. However, there was a mass of material to wade though in trying to undertand:

1. The reasons for bleeding,

2. How the cooling system actually works

So I considered how the system is built, and ended writing the following, (with a view to becoming part of a fact sheet), which explains what I understand as the control principles.

So here it is, and maybe it can have some peer review.

--------

Bongo Cooling System

Control principle

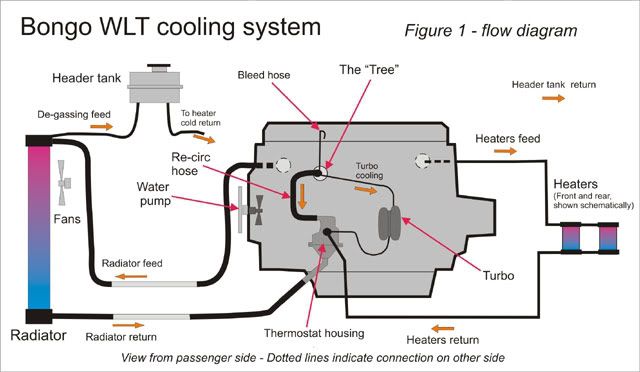

The Bongo WLT diesel engine uses a "constant inlet temperature" system, which may be strange to those familiar with the family saloon with a thermostat on the outlet (eg; “constant outlet temperature” system) but it has been used for very good reasons which are explained later. See Fig 1 when reading the following text.

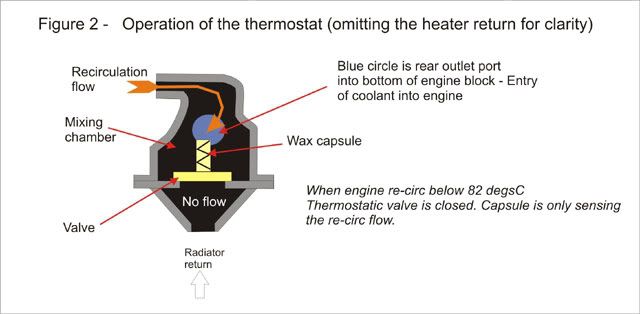

The constant inlet temperature control is obtained by placing the thermostatic valve within a mixing chamber on the engine coolant inlet. The re-circulation hose from the top of the block to the thermostat allows the thermostat to continually sense the engine water temperature. The thermostat’s sensing capsule is situated in a mixing chamber, in which the re-circulation line, the heater return and the radiator return can all mix and influence the opening of the valve.

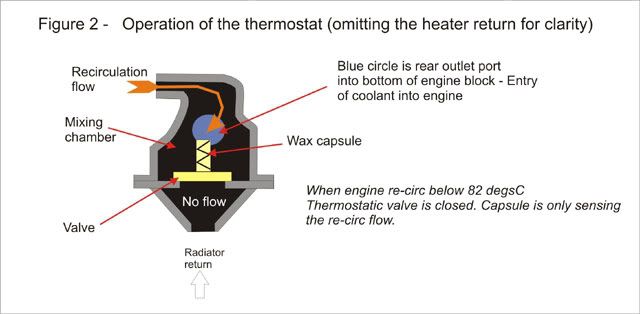

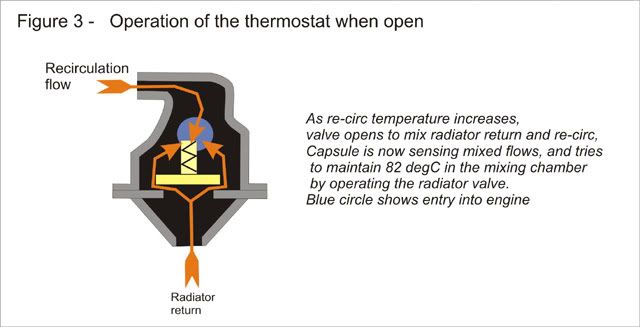

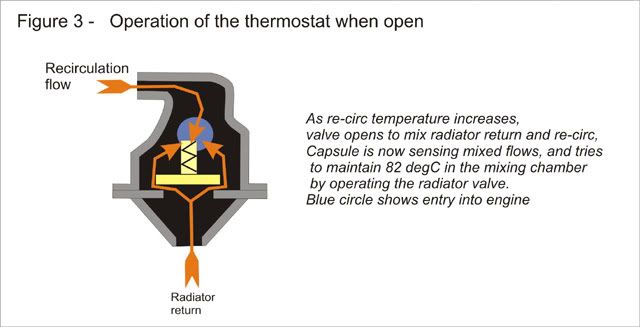

Initially on warm-up the valve is closed, so the only influence on the capsule is the re-circ line and heater returns. When the temperature in the mixing chamber reaches 82 C, the valve will start to open, and additional cool fluid is gradually admitted from the radiator circuit. With increasing engine coolant temperature the thermostat opens until equilibrium is reached and the mix of the three flows settle at somewhere above 82 C in the chamber. The exact temperature will vary a few degrees depending on flows and the thermostat’s response curve, but it can be considered practically as being “constant temperature” control. The re-circ flow will decrease as the thermostat opens.

Changes in engine heating load or cooling effect from heaters and radiator are sensed by the thermostat capsule. For instance; if the heat generated in the engine increases, so will the re-circ temperature, thus opening the valve further. If the ex-radiator coolant temperature drops, then the valve responds to reduce the flow.

This arrangement allows the engine and heater system to get to operating temperature as quickly as possible on start-up.

Fig 2 shows the flows within the thermostat housing when in full re-circulation. Note that the exit flow to the engine is through the cast pipe at the back. Fig 3 shows flows when mixed inlet flows are being sensed.

Constant inlet versus constant outlet control

Constant inlet versus constant outlet control

The constant inlet temperature system has the advantage of giving a tighter temperature control on fluid entering the engine than the "constant outlet temperature" type of control (where the thermostat is on the engine outlet). An outlet control system can only sense the temperature of coolant after it has passed through the engine, when it is too late. Surges of cold fluid, such as when engine speed increases, when ex-radiator coolant temperature drops, or when the thermostat first opens, results in thermal shock to the engine. The Bongo constant inlet temperature system eliminates this.

Implications for air locking of cooling system design

The Bongo has low level pipes feeding the radiator because of the layout of the bodywork. This inhibits the purging of air out of the head, which can cause air locking and subsequent overheating.

The bleed pipe allows the following two crucial bleed operations:

1. When initially filling it bleeds air trapped in the cylinder head.

2. When warming up it allows air released by the opening thermostat to exit the system.

After a coolant system re-fill, the initial opening of the thermostat on warm-up is the point at which retained air in the radiator/thermostat hose is released into the engine and can be trapped in the head. This is when the thermostat opens and the bottom hose get warm. But a considerable coolant velocity would be required to force the large air bubble in the head down the main engine outlet hose and into the radiator. This may not be achieved, so the bleed process is necessary.