Agreed, although it may well take time for the pressure to equalise with no flow. Could you mount this in the expansion tank clear of the coolant?g8dhe wrote:Size of tube has no impact on the pressure if there is no flow in the tube.

Coolant pressure sensor

Moderators: Doone, westonwarrior

Re: Coolant pressure sensor

Re: Coolant pressure sensor

tallbongo wrote:Agreed, although it may well take time for the pressure to equalise with no flow.g8dhe wrote:Size of tube has no impact on the pressure if there is no flow in the tube.

Just realised that bit may look cheeky. It's not meant that way. I'm just pointing out that the sensor will lag behind the pressure of the circulating coolant if mounted near the end of the bleed tube. I've no idea how long the lag will be, but it will be present.

- Driver+Passengers

- Supreme Being

- Posts: 2019

- Joined: Mon Mar 14, 2011 1:56 pm

- Location: Fife

Re: Coolant pressure sensor

Not cheeky in the slightest. It will be interesting to see what is shows.tallbongo wrote:Just realised that bit may look cheeky. It's not meant that way. I'm just pointing out that the sensor will lag behind the pressure of the circulating coolant if mounted near the end of the bleed tube. I've no idea how long the lag will be, but it will be present.tallbongo wrote:Agreed, although it may well take time for the pressure to equalise with no flow.g8dhe wrote:Size of tube has no impact on the pressure if there is no flow in the tube.

Re: Coolant pressure sensor

You don't need a differential sensor just a relative pressure sensor.Driver+Passengers wrote: I am aware that this sensor measures pressure relative to a sealed vacuum, whereas I really want a differential pressure sensor with one port open to atmosphere. I could always use two and compensate in software.

I once did a design using two absolute sensors and subtracting the atmospheric reading - that was for depth sensors which are fitted on the gates of the Thames barrier although that was a simple analogue design into a 4-20mA sensor. If you go that way with compensation in a micro then a barometric sensor gives better resolution as the reference sensor.

I'll be interested to hear how the sensor stands up to the environment, usually they are remote mounted to avoid the heat and vibes, couldn't you mount them on a board and run tubes to the sensors?

1995 Ford Freda, 2.5TD, auto, AFT, side conversion.

Re: Coolant pressure sensor

Thinking about the use of the bleed tube, I wonder if you might get a venturi effect taking place, which might appear to affect the pressure ? It struck me when thinking about the bleeding method and the fact that the water level varies in the funnel depending on engine speed/water pump speed ? See Wikipedia for details http://en.wikipedia.org/wiki/Venturi_effect but with the flow through the 3 way splitter it is probably going to be a restriction/orifice and effect pressure - no idea about how much however depends on the size of the splitter compared to the pipes feeding it.

Geoff

2001 Aero V6, AFT, full side conversion.

2001 Aero V6, AFT, full side conversion.

- Driver+Passengers

- Supreme Being

- Posts: 2019

- Joined: Mon Mar 14, 2011 1:56 pm

- Location: Fife

Re: Coolant pressure sensor

To protect the sensor's gel miniscus from the coolant, the manufacturer has suggested silicone grease, or silicone oil, but prefer grease.

I've managed to get a can of "slide easy", a universal silicone-oil from LIDL (isobutane, propane, butane, mineral oil and bimethicone). The first three I guess are propellants only, but I don't really want them evaporating having already been in contact with the sensor gel miniscus. Also, mineral oil is meant to harm rubbery stuff, isn't it? Not sure I'm going to use that.

Stopping off at the plumbers merchants, they had a large tub of own brand silicone grease from which I was given a pinch in a plastic bag. Not sure of the composition, but didn't seem to advertise itself for high temperature use - more O-rings on push-fit soil pipe and the like. Not convinced - I should probably err on the side of caution, though I'll stick a drop in boiling water and see what happens.

You can get a 20g tube of Carlube multipurpose silicone grease (extreme temp) on eBay for £3, but I can't find anything locally. Rubbish!

(Edit: or 70g for £6 delivered, now ordered...)

I've managed to get a can of "slide easy", a universal silicone-oil from LIDL (isobutane, propane, butane, mineral oil and bimethicone). The first three I guess are propellants only, but I don't really want them evaporating having already been in contact with the sensor gel miniscus. Also, mineral oil is meant to harm rubbery stuff, isn't it? Not sure I'm going to use that.

Stopping off at the plumbers merchants, they had a large tub of own brand silicone grease from which I was given a pinch in a plastic bag. Not sure of the composition, but didn't seem to advertise itself for high temperature use - more O-rings on push-fit soil pipe and the like. Not convinced - I should probably err on the side of caution, though I'll stick a drop in boiling water and see what happens.

You can get a 20g tube of Carlube multipurpose silicone grease (extreme temp) on eBay for £3, but I can't find anything locally. Rubbish!

(Edit: or 70g for £6 delivered, now ordered...)

- Driver+Passengers

- Supreme Being

- Posts: 2019

- Joined: Mon Mar 14, 2011 1:56 pm

- Location: Fife

Re: Coolant pressure sensor

As I've got three sensors in total and want to get going on the sensor tonight, I'll try the first one with the silicone spray I've got. Apparently, dimethicone has been used for heat resistant tiles on re-entry vehicles. I may spray into a cap first and while still fluid, inject into the cavity.

- Driver+Passengers

- Supreme Being

- Posts: 2019

- Joined: Mon Mar 14, 2011 1:56 pm

- Location: Fife

Re: Coolant pressure sensor

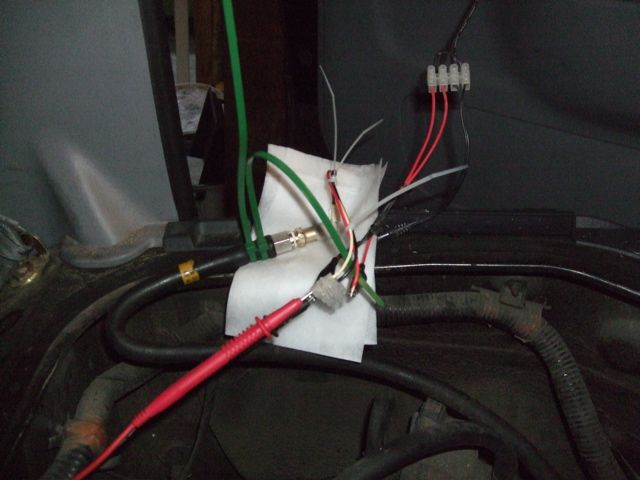

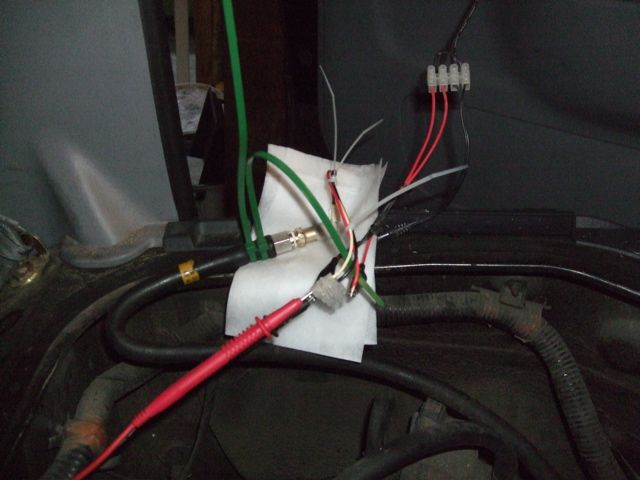

Here's the sensor assembly:

I used the super putty stuff to embed the sensor in the top and then wrapped it up. 10 minutes later I hooked it up to the bike pump and voltmeter and got it up to just over 2bar, reading 3.something Volts and held pressure for over a minute. Good enough for now, and it hasn't even hardened fully, yet.

I used the super putty stuff to embed the sensor in the top and then wrapped it up. 10 minutes later I hooked it up to the bike pump and voltmeter and got it up to just over 2bar, reading 3.something Volts and held pressure for over a minute. Good enough for now, and it hasn't even hardened fully, yet.

Re: Coolant pressure sensor

'Also, mineral oil is meant to harm rubbery stuff, isn't it? Not sure I'm going to use that.'

Hi Matt, I think that mineral oil will only harm natural rubber it should be OK 'I THINK' on synthetic rubber.

Peter

Hi Matt, I think that mineral oil will only harm natural rubber it should be OK 'I THINK' on synthetic rubber.

Peter

Re: Coolant pressure sensor

Are you talking to a UK representative or just their on-line help?Driver+Passengers wrote:To protect the sensor's gel miniscus from the coolant, the manufacturer has suggested silicone grease, or silicone oil, but prefer grease.

1995 Ford Freda, 2.5TD, auto, AFT, side conversion.

- Driver+Passengers

- Supreme Being

- Posts: 2019

- Joined: Mon Mar 14, 2011 1:56 pm

- Location: Fife

Re: Coolant pressure sensor

Online help. I can PM you their full response, if you're interested.Rhinoman wrote:Are you talking to a UK representative or just their on-line help?Driver+Passengers wrote:To protect the sensor's gel miniscus from the coolant, the manufacturer has suggested silicone grease, or silicone oil, but prefer grease.

I used the silicone oil. Just collating the results. Graphs shortly.

- Driver+Passengers

- Supreme Being

- Posts: 2019

- Joined: Mon Mar 14, 2011 1:56 pm

- Location: Fife

Re: Coolant pressure sensor

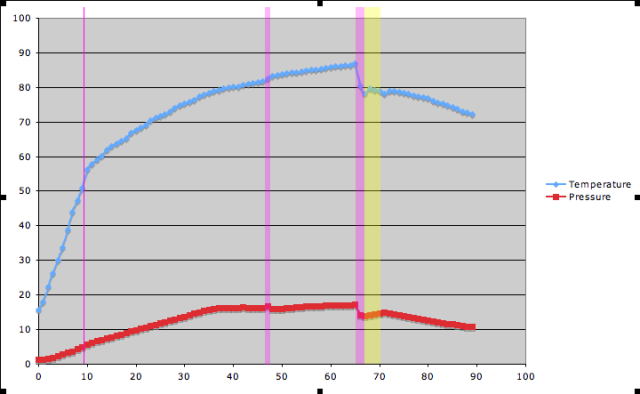

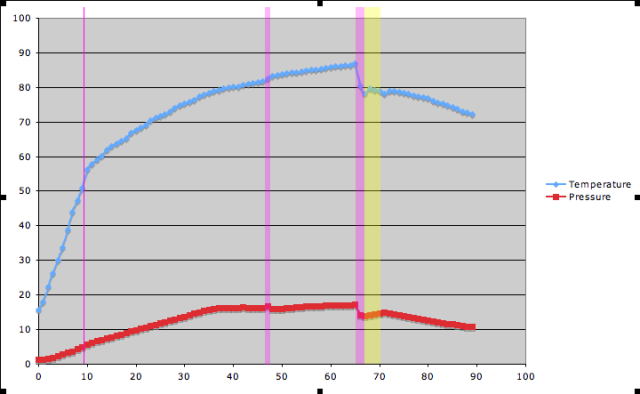

Time: 1h30

Diesel: unknown

Whisky: unknown

First pink line is when the cold-start cut off.

Second pink was 1 minute at 2k rpm

Third pink was full/hot heaters plus A/C for 2 minutes

Yellow was full/hot heaters with no aircon for 3 minutes.

Then I switched the engine off.

No wetness from the header tank overflow.

Several things I can't explain on these graphs. At 36m, why does pressure stabilise but temperature continue to increase (I thought I'd hit cap pressure)? But then, why do I see another 0.9psi on top of that a bit later? I need a view on pressure in header tank. I need temp gauge on bottom hose.

Edit: I happened to do the 1min@2K RPM right around the time the thermostat opened.

I've proven it works, I'm drunk and I'd do things differently on the next test run.

Edit: the fact I'm nudging 16psi all the while is enough to convince me of a gasket/head fault.

Diesel: unknown

Whisky: unknown

First pink line is when the cold-start cut off.

Second pink was 1 minute at 2k rpm

Third pink was full/hot heaters plus A/C for 2 minutes

Yellow was full/hot heaters with no aircon for 3 minutes.

Then I switched the engine off.

No wetness from the header tank overflow.

Several things I can't explain on these graphs. At 36m, why does pressure stabilise but temperature continue to increase (I thought I'd hit cap pressure)? But then, why do I see another 0.9psi on top of that a bit later? I need a view on pressure in header tank. I need temp gauge on bottom hose.

Edit: I happened to do the 1min@2K RPM right around the time the thermostat opened.

I've proven it works, I'm drunk and I'd do things differently on the next test run.

Edit: the fact I'm nudging 16psi all the while is enough to convince me of a gasket/head fault.

- Northern Bongolow

- Supreme Being

- Posts: 7723

- Joined: Mon Mar 15, 2010 11:33 pm

- Location: AKA Vanessa

Re: Coolant pressure sensor

very very very very good mate.

takes things nicely on a big jump.

re your question at 36 mins. look closely at the system temps that will give you your answer.

if you had your temp probe inside the stat housing the results would mean more.

if you had a head problem the pressure would not drop when the heaters were put on, so the answer to your pressure problem is temp related, so !!!.

takes things nicely on a big jump.

re your question at 36 mins. look closely at the system temps that will give you your answer.

if you had your temp probe inside the stat housing the results would mean more.

if you had a head problem the pressure would not drop when the heaters were put on, so the answer to your pressure problem is temp related, so !!!.

- Driver+Passengers

- Supreme Being

- Posts: 2019

- Joined: Mon Mar 14, 2011 1:56 pm

- Location: Fife

Re: Coolant pressure sensor

Forgot to account for the offset voltage indicating 1.25psi at the sensor at rest (cap off) due to the head of coolant above it.

The max (adjusted) pressure seen by the sensor at 65minutes into the test was.......

1.096 bar!

So chances are, before I put the aircon on, had I waited another couple of minutes, I would have heard the cap vent.

The max (adjusted) pressure seen by the sensor at 65minutes into the test was.......

1.096 bar!

So chances are, before I put the aircon on, had I waited another couple of minutes, I would have heard the cap vent.

- Driver+Passengers

- Supreme Being

- Posts: 2019

- Joined: Mon Mar 14, 2011 1:56 pm

- Location: Fife

Re: Coolant pressure sensor

I bet you're going to say "put in a genuine thermostat"? I still can't quite come round to your thinking.Northern Bongolow wrote:very very very very good mate.

takes things nicely on a big jump.

re your question at 36 mins. look closely at the system temps that will give you your answer.

if you had your temp probe inside the stat housing the results would mean more.

if you had a head problem the pressure would not drop when the heaters were put on, so the answer to your pressure problem is temp related, so !!!.

Give me a week or two to get this sensor logging data so that I'm not using notepad and pencil once a minute and I'll give anything a go. I can just about afford the diesel, but I can't afford the whisky!

Edit: this morning, temp 17.2 degC, resting pressure +0.75psi.